One of Cairns’ most well- known butchers, Byrnes Quality Meats, is celebrating their 60-year anniversary this year. This remarkable business milestone is a testament to the quality produce and high level of service that the Byrnes family has provided Far North Queensland with for more than half a century.

Originally a carpenter, D’Arcy purchased his first butcher shop in 1960 in Atherton with his wife, Raylee, after trading in his Mareeba milk run business. It was from these humble beginnings that D’Arcy quietly went

about building his empire.

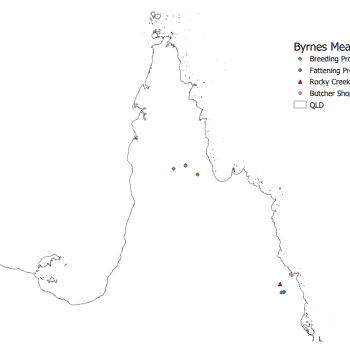

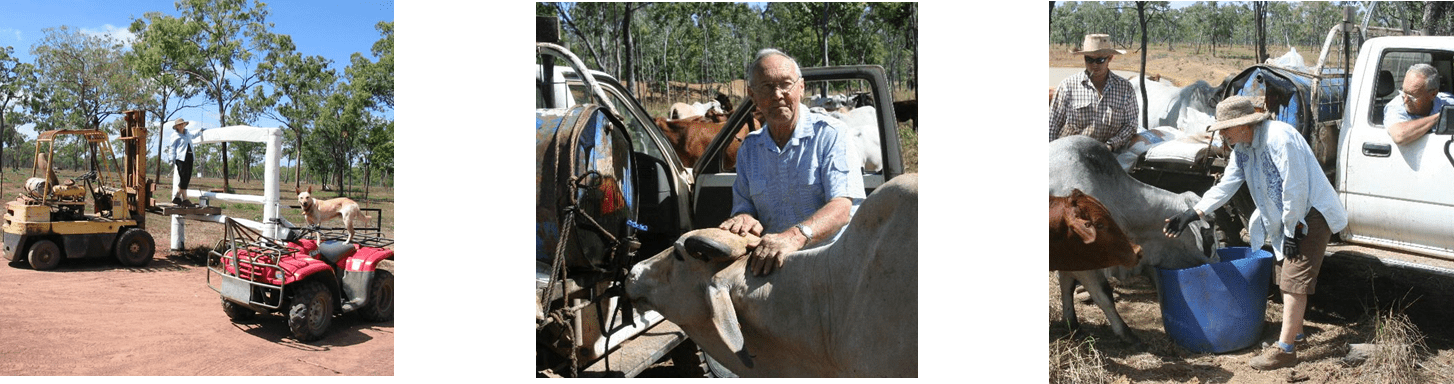

With the ongoing expansion of the region, the family moved from the Tablelands to Cairns and constructed their first wholesale outlet, Byrnes Quality Meats on Mayers Street in Manunda. The family continued to invest in an extensive range of businesses within the meat industry so that they could be from paddock- to-plate. They have breeding programs, three cattle stations covering 1.5 million acres near Coen in Cape York and properties over Queensland, the Rocky Creek abattoir, and a string of small butcher shops across Cairns, including at Smithfield, Holloways Beach, Earlville Shopping Centre and Cairns Central.

“We bought property in Cape York in 2001 and bought another one there a couple of years ago.” “We also purchased a farm in Malanda, to which we send our steers from the Cape to fatten, continuing our paddock-to-plate scenario. The Byrnes family smile when we hear some people announce they are paddock-to-plate as if it is something new – our family has been paddock- to-plate since the ‘60s!”

“The ability to breed, fatten and process our own cattle through our family-owned abattoir provides us with a unique opportunity to practically implement and refine the principles of meat science that influence eating

quality. This allows us to consistently produce high quality red meat with great eating quality” says Mr. Byrnes.

The quality of Australian meat is recognised worldwide, and Mr and Mrs Byrnes pride themselves on being able to not only match this high standard, but exceed it regularly, and more than 15,000 local customers agree – Byrnes Quality Meat can’t be beaten either for quality or value.

They also handle a variety of small stock, including pigs and sheep, as well as the beef from their own farms, Byrnes supply a complete range of popular meat and groceries, as well as poultry, fish, smallgoods and exotic meat lines such as kangaroo and crocodile.

Byrnes Quality Meats is now a third-generation family business, with D’Arcy’s’ son, Victor Byrnes, and now Victors’ son, Cailan Byrnes, stepping into the business. Supported by a loyal cohort of staff, Byrnes Quality Meats is proud to be able to supply North Queensland with high quality, tender and tasty red meat.

In celebrating the business’ 60th anniversary, the Byrnes family would like to say a big thank you to all their past and current employees, customers and anyone else that has supported the business over the years.

And here are some interesting facts you may not know about meat.

TABLELAND BLUE – PREMIUM GRASSFED BEEF

Tableland Blue premium grass-fed beef is raised on the fertile volcanic soils of the Atherton Tablelands. Reliable rainfall and tropical climate, allows us to grow quality nutritious grass all year-round. This is valued by our group of likeminded family-owned producers who supply Tableland Blue Beef. The ability to locally produce and process our beef reduces animal stress and promotes better animal welfare. The result is tender, high quality, tasty red meat.

OUR DIFFERENCE

The ability to breed, fatten and process our own cattle through our family-owned abattoir provides us with a unique opportunity to practically implement and refine the principles of meat science that influence eating quality. This allows us to consistently produce high quality red meat with great eating quality.

Byrnes Meat Assurance (BMA) is a series of standard operating procedures and assessments that we have created in-house to ensure consistency in quality. The key attributes that we use for our BMA assessment include animal stress, pH, meat colour, fat characteristics, ossification, and minimum ageing requirement.

These attributes are assessed at different stages of processing:

1. PRE-PROCESSING

Animal stress

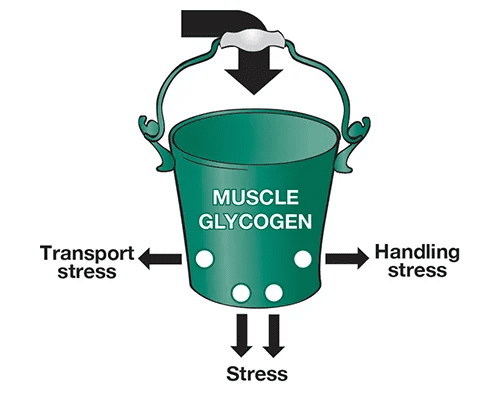

Live animal stress during the pre-processing stage can result in a depletion of glycogen reserves in the animal’s muscle. This results in an increase in the meat pH which causes the meat colour to darken, decreases shelf life and causes eat quality and cooking inconsistencies. This can be minimised by reducing transport and handling stress and maintaining a nutritious diet.

2.DURING PROCESSING

pH

pH is a measure of the acidity or alkalinity level of the meat. During processing animal muscle glycogen is converted to lactic acid, which causes the pH to decrease. If muscle glycogen reserves are depleted, it limits the production of lactic acid and the pH increases. Meat with pH levels between 5.7 – 5.3 are more likely to provide consistent eating quality. Minimising stress and ensuring animals have enough energy reserves through adequate finishing assists in achieving an ideal pH-level.

Meat Colour

Meat colour is scored against a set of colour reference standards that reflect the bright cherry red colour that consumers expect. Stress can play a significant role in meat colour as it affects meat pH levels.

Fat Characteristics

Adequate fat coverage is measured to ensure meat is not cooled too quickly which can increase toughness. Fat colour is also measured and is assessed by looking at the colour of the intramuscular fat lateral to the ribeye muscle. Fat colour does not impact eating quality but can have lower consumer appeal.

Ossification

The maturity of a carcass is measured by ossification, which is the process of cartilage turning to bone in the vertebrae. As an animal matures, the fibres in the meat become progressively stronger, more rigid and are less likely to be broken down in cooking, resulting in tougher meat. Poor nutrition during early animal growth stages can increase ossification compared to animals of the same age that have received optimal nutrition.

3. POST-PROCESSING

Minimum ageing requirement

Ageing is a result of the naturally occurring enzymes breaking down the muscle fibres, which results in improved tenderness and beef eating quality. Research has shown the maximum tenderness achieved ageing occurs in the first 21 days. We have a minimum requirement to age our beef for 21 days in vacuum-sealed plastic bags, which can be stored in refrigeration for up to 12 weeks.